COOLING TOWER CHEMICAL

Cooling towers operate using heat exchange. The systems continuously circulate water, however the water that goes through the cooling system is often contaminated, which can lead to scale and corrosion.

A cooling water system that is not properly pre-treated might be exposed to scaling, corrosion, biofouling and may also serve as a breeding ground for hazardous microorganisms. This fouling, corrosion, deposition, and bacterial growth can disrupt all your processes. Your tower’s ability to cool water is compromised if scale, grime, or microbial accumulation is present, leading you to face higher operational and energy expenditures.

Note:The cost of damages caused by scale and corrosion worldwide in Cooling towers and circulation pipes are estimated to be more than 150 billion Euros ($200Billion) annually. The conventional water softeners or chemicals do not yield satisfying results.

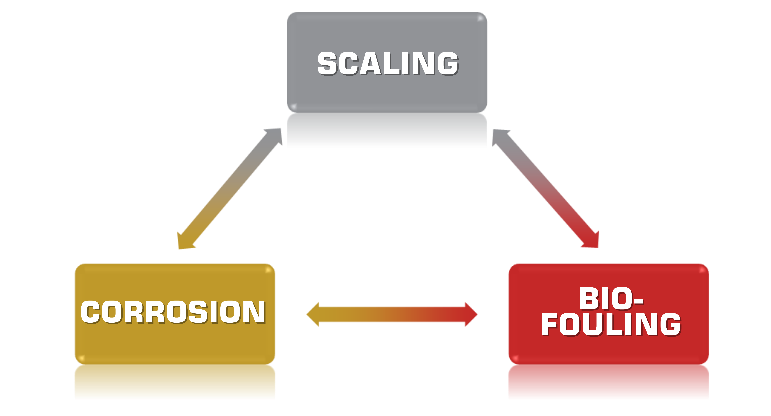

Scaling, Corrosion and biofouling are three primary problems that most waters cause to cooling systems. Thee three are interlinked to each other and one can be the cause of the other. Scaling is the deposition of minerals on boiler surfaces, whereas corrosion causes the degradation of metal parts when corrosive water reacts with it, resulting in leaks and structural damage. Scaling lays the groundwork for the growth of biofilms, and corrosion quickens the deterioration of metal surfaces inhabited by biofouling. To properly address these issues, a thorough strategy involving water treatment is required to guarantee the best performance and lifetime of boiler systems.

Typically, water treatment for cooling systems involves the use of:

- Scale and corrosion inhibitors

- Closed system treatments – Problems, such as oxygen pitting, are common in closed-loop systems. A variety of chemicals can be used to prevent such corrosion from occurring.

- Biocides – To prevent the growth of possibly hazardous microorganisms.

- Disinfectants- To kill microorganisms and stop their recurring growth

- Organic dispersants – To prevent fouling and the buildup of biofilms.

OUR-

SOLUTION

ADVANTAGES OF

POWDERED CHEMICALS

CONVENTIONAL CHEMICALS

Takes more space

High Transportation Costs

High Moving Costs

Dangerous while Handling

INSTANT CHEMICALS

Less Space & Easy Storage

Low Transportation Costs

Maximum Efficiency

Zero Handling Risks Biodegradable Chemicals

TOTAL PROTECTION FOR YOUR COOLING TOWER,

AIR CONDITIONERS AND HEAT EXCHANGERS

FREQUENTLY ASKED

QUESTIONS

1. Why does cooling tower need chemical treatment?

Our cooling system water treatment products have the objective of safeguarding the cooling stower and other cooling systems by preventing corrosion and scale buildup, as well as destroying any kinds of bacterial growth.

2. What is the difference between INSTANT I-SOFT OB and INSTANT I-SOFT NB?

Both INSTANT I-SOFT OB and INSTANT I-SOFT NB perform the same functions, i.e., protection of your cooling system and prolonging its life. INSTANT I-SOFT NB contains a very strong biocide along with the general I-SOFT (Scale and Corrosion prevention), hence provides a long term protection against microbiological buildup. The biocide in INSTANT I-SOFT OB is an ‘oxidising biocide’ similar like hydrogen peroxide, chlorine, etc but much better.

3. Why are there two different types of cooling system chemicals?

Although, the biocide in INSTANT I-SOFT NB is very strong, some microorganisms can develop resistance to it over time. So, a ‘shock treatment’ in the form of INSTANT I-SOFT OB is generally dosed after a specific interval of time to kill all the resisting microorganisms.

Note: Since, I-SOFT OB is very strong, so it is advisable to dose I-SOFT NB on a regular basis and I-SOFT OB just as a shock treatment.

4. How much of each chemical is required to be dosed to achieve an effective water treatment for the cooling system?

The ratio of INSTANT I-SOFT NB and INSTANT I-SOFT OB is generally kept at 6 days of NB and then 1 day of OB. This ratio is variable and depends upon the application. Please refer to the data sheet to get an overview of the exact dosing rates or please consult us for a personalised consultation.

5. Are the INSTANT I-Soft chemicals expensive?

The INSTANT I-Soft chemicals come in powder form and unlike in case of liquid chemicals available in market, you don’t need to pay for the water in chemicals. Our chemicals are way more economical than our competitors.

6. Are the INSTANT I-Soft chemicals heavy?

The Instant I-Soft range of chemicals come in POWDER form and are extremely easy to transport, saving you a ton load of money.

- Multi-functional Scale and Corrosion inhibitor with Dispersant.

- OXIDIZING BIOCIDE (OB) for “shock treatment”.

Can effectively destroy all kinds of microorganisms and bacteria, especially Legionella in just seconds.

- Multi-functional Scale and Corrosion inhibitor with Dispersant.

- NON-OXIDIZING BIOCIDE (NB) for high silica and sulphate content in feed water.

High performance product formulated without any Phosphates and Phosphonates.

THE INSTANT I-SOFT RANGE OF CHEMICALS IS EXCELLENT FOR

Drinking Water Treatment

Drinking Water Treatment