BOILER WATER TREATMENT

CHEMICALS

Boilers are meant to heat up water, the vapours from which can be used for cooking, sanitation or for other industrial purposes. Boiler water treatment is basically the treatment and conditioning of feed water with three primary goals, i.e., corrosion prevention, scale prevention and maintaining steam purity and quality.

Note- Scale formation can be very costly. A calcium carbonate scale deposit of less than 0.25mm can result in a 7% reduction in energy efficiency

PROBLEMS IN ALL

WATER TREATMENT INDUSTRIES

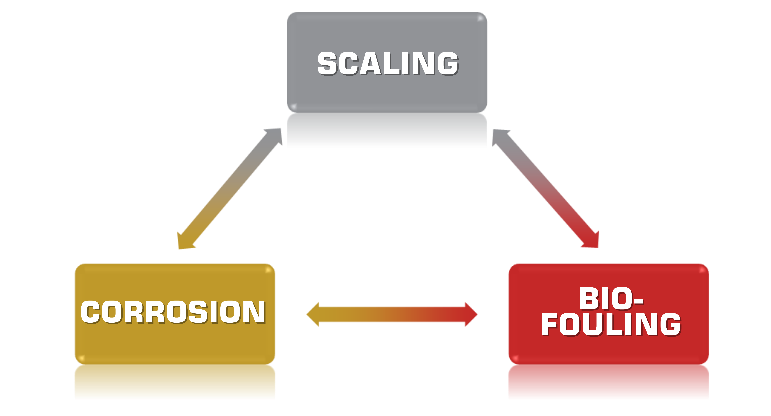

Scaling, Corrosion and biofouling are three primary problems that most waters cause to boilers. Thee three are interlinked to each other and one can be the cause of the other. Scaling is the deposition of minerals on boiler surfaces, whereas corrosion causes the degradation of metal parts when corrosive water reacts with it, resulting in leaks and structural damage. Scaling lays the groundwork for the growth of biofilms, and corrosion quickens the deterioration of metal surfaces inhabited by biofouling. To properly address these issues, a thorough strategy involving water treatment is required to guarantee the best performance and lifetime of boiler systems.

HOW WE MAKE A

DIFFERENCE

ADVANTAGES OF

POWDERED CHEMICALS

CONVENTIONAL CHEMICALS

Takes more space

High Transportation Costs

High Moving Costs

Dangerous while Handling

INSTANT CHEMICALS

Less Space & Easy Storage

Low Transportation Costs

Maximum Efficiency

Zero Handling Risks Biodegradable Chemicals

COMPLETE BOILER

PROTECTION

FREQUENTLY ASKED

QUESTIONS

1. Why does boiler water need chemical treatment?

Our boiler water treatment products have the objective of safeguarding the boiler and steam system by preventing corrosion and scale buildup, as well as ensuring the maintenance of steam purity and quality.

2. Are the INSTANT I-Soft chemicals expensive?

The INSTANT I-Soft chemicals come in powder form and unlike in case of liquid chemicals available in market, you don’t need to pay for the water in chemicals. Our chemicals are way more economical than our competitors.

3. Why should the conventional water softeners not be used for boiler water treatment?Why should the conventional water softeners not be used for boiler water treatment?

The conventional water softeners release about 0.79 mg/L of carbon dioxide for each mg/L of Sodium bicarbonate (NaHCO3). As the steam is condensed, carbon dioxide dissolves in water and decreases the pH by increasing hydrogen ion concentration as shown in the following sequence,

CO2 + H2O = H2CO3 (Carbonic Acid) ↔ H+ + HCO3– (+Fe) → Fe(HCO3) + H2

This Carbonic acid promotes the iron corrosion reaction by supplying a reactant H+. Low pH causes a generalized loss of metal rather than the localized caused by oxygen corrosion. The combination of adding sodium ions in water, contributes to formation of scale as Sodium Carbonate in hot water boilers and Sodium Silicate and Sodium Iron-Silicate in Steam boilers.

4. Are the INSTANT I-Soft chemicals heavy?

The Instant I-Soft range of chemicals come in POWDER form and are extremely easy to transport, saving you a ton load of money.

5. Why does steam boiler and hot water boiler need different chemicals treatment?

The condensate water generated by a steam boiler possesses a high corrosive potential towards piping, leading to detrimental effects on the boiler and necessitating costly repairs to rectify the problem. Thus for steam boilers, we recommend doing Instant I-Soft OV which breaks down to form neutralizing amines which elevate the pH of the condensate systems, helping to protect it from any gaseous attacks.

Drinking Water Treatment

Drinking Water Treatment