Granulated Activated Carbon

Introduction

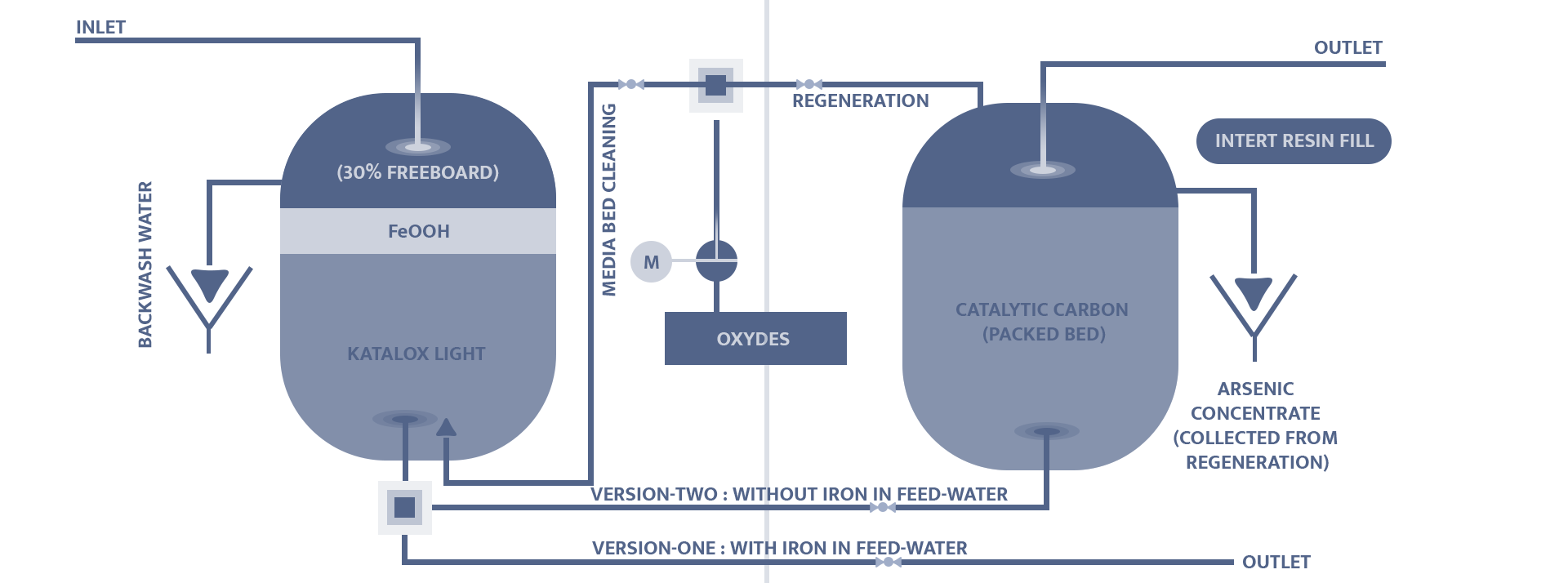

CATALYTIC CARBON is made of activated coconut shell carbon. This Granulated Activated Carbon which is (highly

activated) by catalysed iron-hydroxide, which enhances the adsorption of contaminants that have negative charge. CATALYTIC CARBON is the only available Carbon in the market which is regenerable. Iron Catalyst has the highest Oxidation and Adsorption pores “Inside as well as Outside the Activated Carbon.

Media Description: High content (10%) Feroxyhyte (FeOOH) coated GAC

CATALYTIC CARBON Removal methods:

1. Mechanical Filtration (fine particles, TSS, Turbidity down to 1 micron)

2. Adsorption of organic contaminants

3. Adsorbtion of inorganic contaminants (e.g. As, Heavy Metals, Radionuclides)

| Filtration (≤ 1 µm) of | Removal of | Best features | Regeneration of Catalytic-Carbon with OXYDES-P |

|---|---|---|---|

| Total Suspended Solids | Humic Substances | Feroxyhyte coated Granular Activated Carbon | Usage: 1% Concentrated Solution of OXYDES-P |

| Sediments | Tanins & Lignin | Very high surface area | Usage: 1% Concentrated Solution of OXYDES-P |

| Turbidity | Color & Odor (organic) | Chemically Regenerable with OXYDES & OXYDES-P | |

| Chloramines | No mandatory dosing required | ||

| Trihalomethanes (THMs) | Light weight media - saves backwash water | ||

| Phenols & p-nitro phenol | Replacement frequency : every 2 - 5 years | ||

| All kind of Dyes | pH regulation in the range of 6.5 - 6.9 is strongly recommended for removal of Cr(III) and As(III) | ||

| Phenols & p-nitro phenol | |||

| Inorganic (Arsenate, Arsenide, Chromium, Copper, Cyanide, Fluoride, Lead, Mercury & Selenium) |

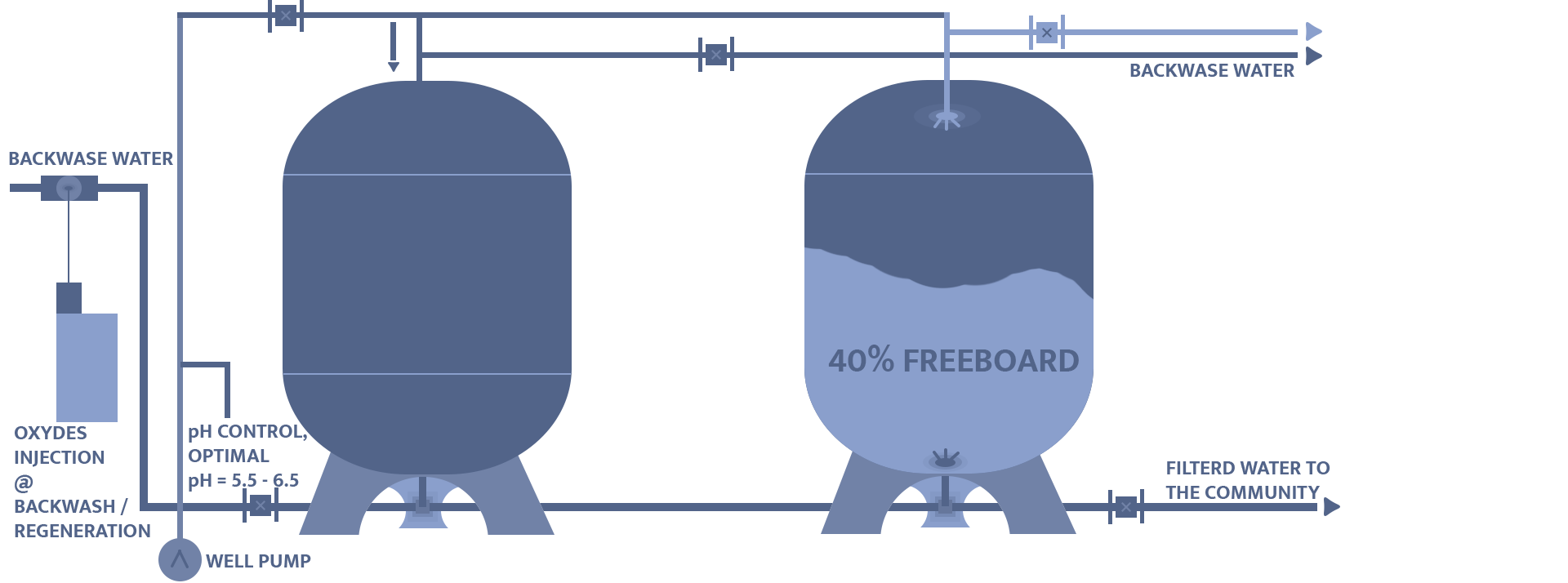

Drinking Water Treatment

Drinking Water Treatment