Introduction

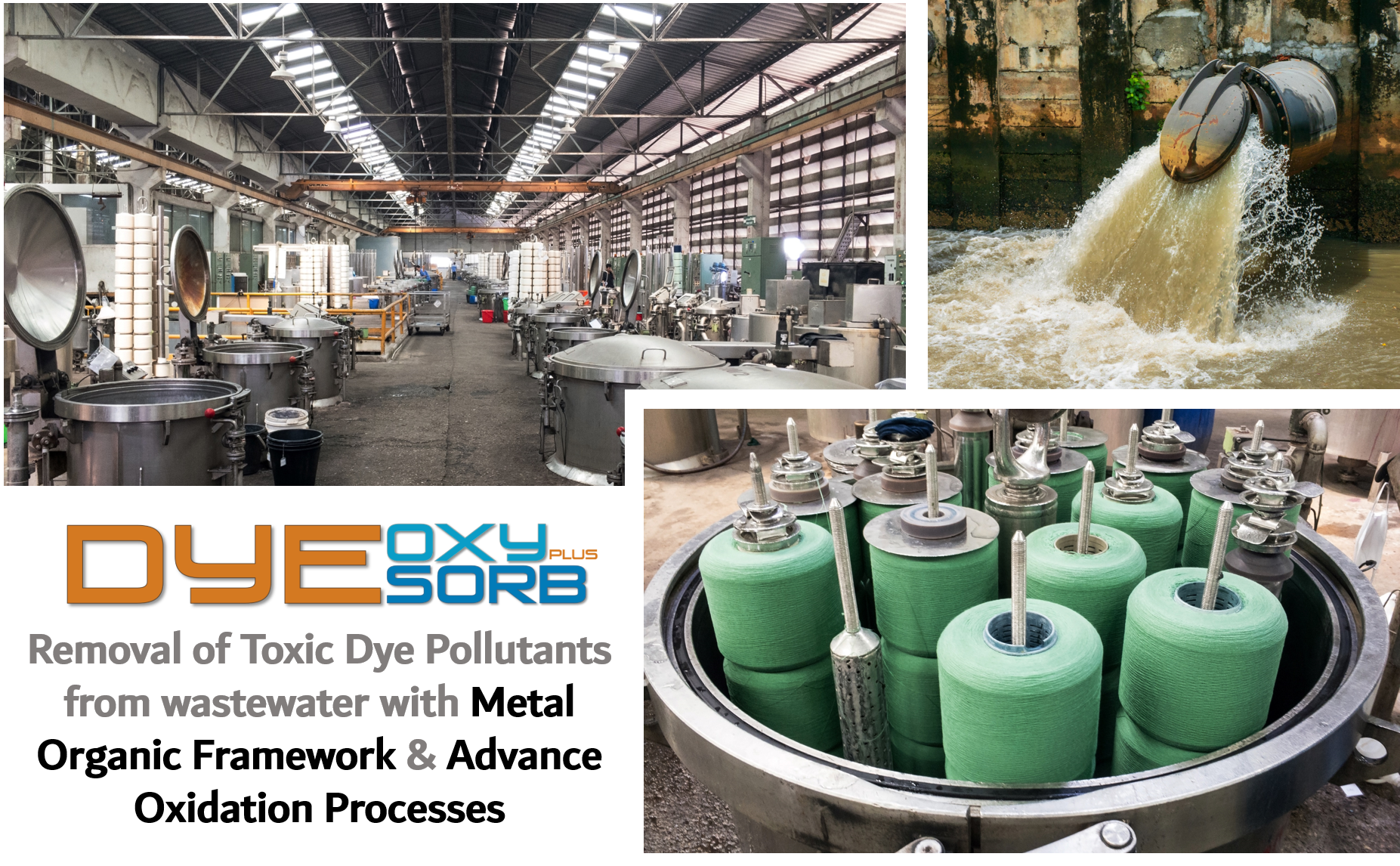

DyeOxy® and DyeSorb® is a two-step process for the removal of all types of dyes including many other pollutants from water or wastewater. The most effective process to attain the efficient degradation of industrial dyes. Dyes are used in various industries as coloring agents. The discharge of these dyes, specifically synthetic dyes in wastewater represent a serious environmental problem and cause public health concerns.

Dyes consist of many toxic materials and causing serious harmful impacts on the environment. Tons of dyes are discharged daily into the environment as aquatic waste. The wastewater from these industries contains very high levels of Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).

Drinking Water Treatment

Drinking Water Treatment