ADVANCED CATALYTIC FILTRATION MEDIA FOR IRON, MANGANESE AND HYDROGEN SULFIDE REMOVAL

Introduction

Katalyst Light is formally known as Katalox-Light***

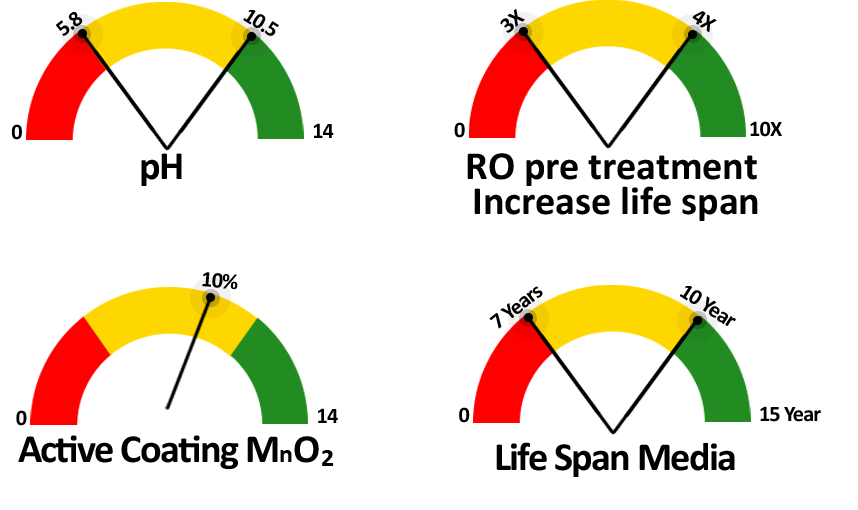

KATALYST LIGHT® innovative filtration media is exclusively manufactured in Germany. It is engineered with a unique MnO2 coating on the exceptional base material ZEOSORB®. KATALYST LIGHT® boasts exceptional attributes: it is lightweight, presents an expanded filtration surface, endures an extended service life, and guarantees steadfast performance, capable of filtration down to 3 microns. Its applications encompass a wide spectrum of tasks, including high-level filtration, elimination of color and odors, removal of Iron, Manganese, and Hydrogen sulfide, as well as the efficient reduction of Arsenic, Zinc, Copper, Lead, Radium, Uranium, and other radionuclides and heavy metals.

High content (10%) gamma Manganese dioxide (MnO2) coated ZEOSORB®

Katalyst-Light Removal methods:

1. Mechanical Filtration (fine particles, TSS, Turbidity etc.)

2. Catalytic precipitation and sorption (Fe, Mn, Cu, Pb etc.)

3. Adsorbtion (flocculant formation and adsorption of As, Heavy Metals, Radionuclides)

Filtration (≤ 3 µm) of:

♦ Sediments

♦ Turbidity

♦ Organics

♦ Colour (some, organic)

♦ Odour

Removal of:

♦ Manganese (Inlet conc. up to 20 mg/L)

♦ Arsenic

♦ Hydrogen Sulfide

♦ Uranium, Radium

♦ Heavy Metals

♦ Radionuclide

Best features:

♦ Very high surface area

♦ High MnO2 coating (10%)

♦ Contains NO crystalline Silica

♦ No mandatory dosing required

♦ Light weight media – saves backwash water

♦ Replacement frequency every 7-10 years

FEATURE

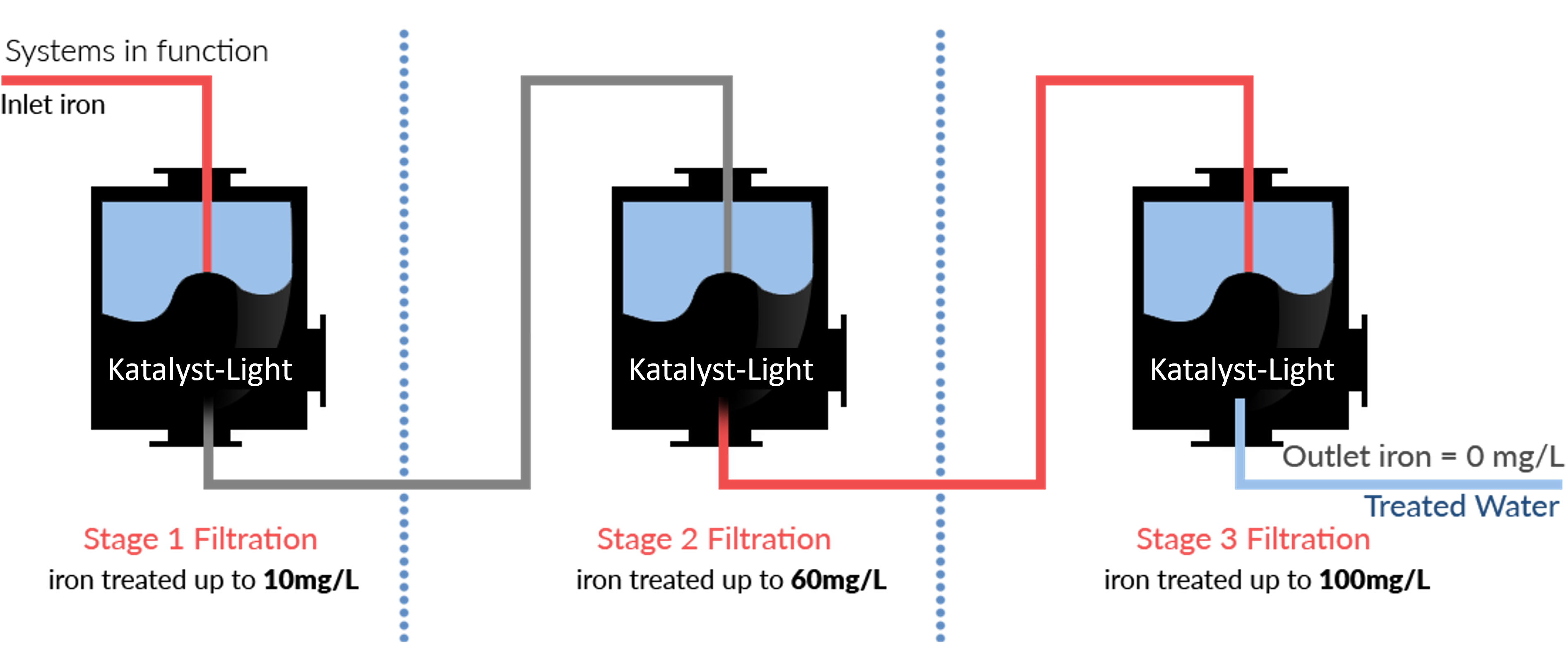

BREAKTHROUGH IN IRON REMOVAL TECHNOLOGY!

Real installations from different part of the world have been reported to remove unchallenged amounts of iron. In a few extreme cases multi-stage Katalyst-Light filtration systems have been used without the use of any chemicals to remove iron with inlet concentration of as high as 60 – 100 mg/L (ppm).

These astounding findings are being further investigated to find the correlation between removal limit and underlying ORP, pH and other possible governing characteristics.

Submit your test data to help us to model a better and accurate System Calculator for Katalyst-Light media.

Advanced Features of

Katalyst-Light | Advanced Applications

Fracking

Reducing radionuclide waste in fracking wastewater

Industrial Wastewater

Reducing radionuclide waste in fracking wastewater

Cooling tower re-circulation

Dramatically reducing the blow-down water and using part of it in re-circulation process

Reverse Osmosis Pre-treatment

Increasing the membrane life-span 3-4 times more

Removal of Arsenic

by the method of

co-precipitation

Radionuclide removal

Radium,

Uranium

SYSTEM

CALCULATION

Recommendation on Katalox Light System Calculation

Please enter Following Values :

Flowrate :Iron(Fe) : mg/l (ppm) (Recommended inlet pH 7.5)

Manganese(Mn) : mg/l (ppm) (Recommended inlet pH 8.5)

Note: This is a standard calculation based on raw water pH 7.5 for iron removal and 8.5 for manganese removal.

If the raw water pH is not as mentioned above, then we highly recommend to increase the pH using Sodium Hydroxide (NaOH).

Watch Water’s Recommendation

| Katalox Light Media Require | 0 | Liters |

| Katalox Light Media Require | 0 | Bag(ft3) |

| Freeboard | 0 | % |

| Required Vessel Volume | 0 | Liters |

| Filtration Rate | 0 | BV/h |

| EBCT(Contact Time) | 0 | Seconds |

*This calculator has been designed based on real time data obtained from system installation worldwide.

*The contamination concentration and the filtration rate is best-fit approximation and is subject to be updated.

*This calculation is only a recommendation for system design. Please do not forget to read and follow the instruction given in our Katalox Light product literature.

COMPARISON

CHART

Why Katalyst-Light is "The Best" compared to other products in the market?

Much higher gamma Manganese coating (10%) for better filtration, more service life, while keeping the bulk density close to the density of water 1000 kg/m³ (Katalyst-Light Bulk Density: 1060 kg/m³).

Advantages Of Katalyst-Light

Katalyst-Light is produced in Germany from ZEOSORB® as a raw material. Katalyst-Light the lightest, to Greensand and Filter-OX, the heaviest. The Katalyst-Light media is the only catalytic media with the highest surface area which removes turbidity, suspended solids up to less than (< 3 microns).

The major advantage of Katalyst-Light is the slower head loss which leads to longer operation time. Katalyst-Light presents a rough and high surface characterized by a high number of pores and crevices. Accordingly, the structural and the texture is considerably different from Greensand Plus and Filter-OX. As a result, this allows slower head loss development, but at the same time causes higher pH and higher removal of iron and manganese without using any chemicals. Application of Katalyst-Light media can produce high-quality water without iron, manganese, and turbidity. Additionally, backwashing water demand is 60% less than Greensand Plus and Filter-OX.

| Katalyst Light | Greensand Plus | Filter-OX | |

| Certification | IAMPO Tested and Certified to NSF/ANSI/CAN Standard 61 and 372 Lead Free | WQA Tested and Certified to NSF/ANSI/CAN Standard 61 | WQA Tested and Certified to NSF/ANSI/CAN Standard 61 |

| Turbidity | Excellent | No | No |

| Suspended Solids | Excellent | No | No |

| Iron | Up to 100 mg/l | ≥ 15 mg/l | No Data |

| Manganese | Up to 20 mg/l | No Data | No Data |

| Arsenic | Depends on Iron Content Fe:As≥ 20:1 | Depends on Iron Content Fe:As≥ 20:1 | No Data |

| Active Ingredient (MSDS) | Gamma Manganese Dioxide (MnO2) ≥ 10% ZEOSORB® = 85% No Silica (SiO2) |

Manganese Dioxide (MnO2) = 3.2–4.8% Quartz (SiO2) = 90.4–93.6% |

Manganese Dioxide (MnO2) = 10-20% Quartz (SiO2) = 55–85% |

| Surface Area | 320 m2/gram | No Data | No Data |

| Effective Particle Size | Uniform Size (0.6–1.4 mm) |

(0.25–1.0 mm) | (0.354–1.0 mm) |

| Product Weight | Light (1060 grams/liter) |

Heavy (1,425 grams/liter) |

Heavy (1,345 grams/liter) |

| Shipping Weight | 66 lbs./ft3 30 kg/ft3 (Light) |

89 lbs./ft3 40 kg/ft3 (Heavy) |

84 lbs./ft3 38 kg/ft3 (Heavy) |

| Packaging | 1 ft3(28 .3 liters) /bag 40 bags(1,132liters)/pallet |

0.5 ft3(14 .1 liters) /bag 55 bags(779 liters)/pallet |

0.5 ft3(14 .1 liters) /bag 48 bags(679 liters)/pallet |

| Service Flow Rate | 4–12 gpm/ft2 (10–30 m/h) |

5–12 gpm/ft2 (12.5–30 m/h) |

2–12 gpm/ft2 (5–30 m/h) |

| Backwash Flow Rate | 10–12 gpm/ft2 @ 55 °F (25–30 m/h) |

12 gpm/ft2 @ 55 °F (30 m/h) |

12 gpm/ft2 @ 55 °F (30 m/h) |

| Initial Start Up | Backwash approximately 20 minutes or until backwash water is clear as Katalyst-Light is Absolute Dust-Free | Requires minimum 4 hours Cl2 regeneration | Cl2 sterilization recommended but not required |

| Regeneration Chemical | No chemicals required | Intermittent or continuous feed using Cl2or O2 | Intermittent or continuous feed using Cl2or O2 |

| Clean Filter Pressure drop @ 5 gpm/ft2 / (12.5 m/h) | 0.8 psi per foot of bed depth | 0.8 psi per foot of bed depth | 0.8 psi per foot of bed depth |

| Commercial System Larger than 36” Tanks | Same as Above No Air/Water Scour Backwash |

Air/Water Scour Backwash | Air/Water Scour Backwash |

| Installation Allowed in California | Yes | No | No |

| Made in: | Germany | Brazil | Ukraine |

REFERENCES

APPLICATION AND LOCATION

México

Maija, Spain

Amalfi Coast Resort, Florida, USA

Thessaloniki, Greece

California, USA

Florida, USA

Florida, USA

Florida, USA

Accra, Ghana

China

Austria

using Katalyst Light

REPORTE Katalyst Light

Mexico

Mexico City

Hidaldo, Mexico

Vietnam

FREQUENTLY ASKED

QUESTIONS

Katalox Light® (Katalyst Light®) is an advanced filtration media developed in Germany for the removal of iron, manganese, hydrogen sulfide, and other contaminants. Its highly active surface enables fine filtration down to 3 microns and highly efficient removal of iron and manganese.

Katalox Light® (Katalyst Light®) outperforms conventional media like sand, BIRM, DMI-65, ManganOx, FilterOx, Pyrolox and Greensand Plus thanks to its high surface area, Katalox-Light Catalytic Gamma MnO₂ coating, and low density — resulting in superior filtration and reduced maintenance.

It is produced at our manufacturing facility in Mannheim, Germany.

Katalox Light® (Katalyst Light®) features a 10% Gamma MnO₂ coating on a ZEOSORB® core, providing a very high surface area, lightweight handling, and excellent catalytic performance. The use of chemicals and generally not required compared to other filter materials in the market.

Katalox Light® (Katalyst Light®) effectively removes:

- • Iron (Fe)

- • Manganese (Mn)

- • Hydrogen sulfide (H₂S)

- • Turbidity and suspended solids

- • Arsenic, uranium, radium, and other heavy metals (when iron is present)

Fill the vessel to approximately 60 % of its internal volume with Katalox-Light, leaving about 40 % freeboard (empty space). This freeboard provides room for proper bed expansion during backwash and ensures adequate empty-bed contact time (EBCT) for effective treatment.

Size the system so the filtration flow does not exceed the manufacturer’s recommended range for the selected tank.

Typical design guidelines: 10–30 m/h (≈ 4–12 gpm/ft²).

The goal is to maintain sufficient EBCT—excessively high flow reduces contact time and can lead to iron or manganese breakthrough. An optimal bed depth is 80–120 cm (≈ 31.5–47 in.).

Tip: Refer to the official Katalox-Light Engineering Guide for recommended gpm or m³/h values for your vessel size.

- • Insufficient EBCT may prevent complete oxidation or filtration of metals such as manganese.

- • Inconsistent water quality and reduced filtration efficiency.

- • Higher pressure drop and more frequent maintenance.

No. Mixing Katalox-Light with other filter materials (e.g., calcite, Trappsorb, sand) is not recommended.

Different media densities cause stratification and channeling, leading to uneven chemical conditions and compromised performance.

Maintain a feed-water pH of around 8.5 to ensure reliable manganese oxidation on the Katalox-Light surface.

If pH adjustment is necessary, install a dedicated pH-correction stage upstream—for example, a separate vessel containing a pH-raising medium.

Do not mix pH-adjusting media directly with Katalox-Light.

Always place pH-raising media in a separate upstream vessel.

This ensures stable pH control and keeps the Katalox-Light bed operating under optimal conditions.

No. Combining Katalox-Light with other fine filtration media in the same vessel can create inconsistent filtration layers and reduce system reliability.

The freeboard—the empty space above the media—serves several critical functions:

- • Allows the bed to expand and clean properly during backwash.

- • Prevents media loss.

- • Maintains the correct hydraulic conditions for effective treatment.

Carry out regular backwashing according to your system’s design specifications to remove trapped solids and re-classify the bed.

Frequency depends on feed-water quality and flow rate but must be sufficient to keep the media bed clean and evenly distributed.

Contact your authorized Katalox-Light distributor or technical representative, or refer to the official Katalox-Light Engineering Guide for detailed sizing tables and flow-rate recommendations.

It filters particles as small as 3 microns and efficiently removes turbidity, iron, and manganese.

The high concentration of catalytic Gamma (10%) MnO₂ ensures strong oxidation and co-precipitation of contaminants. Unlike heavier or lower-grade media, Katalox Light® (Katalyst Light®) is lightweight yet highly effective due to its superior Gamma (10%) MnO₂ content.

Yes. Katalox Light® (Katalyst Light®) is certified under:

NSF/ANSI/CAN 61 for drinking water safety

NSF/ANSI/CAN 372 for lead-free compliance

Katalox Light® (Katalyst Light®) is ideal for any application which has Iron, Manganese, Hydrogen Sulfide present:

- • Residential well water systems

- • Commercial and industrial water treatment

- • Municipal drinking water systems

- • Reverse osmosis (RO) pre-treatment

- • All ground/surface water for removal Iron, Manganese, Hydrogen Sulfide

Yes — when iron is present, Katalox Light® (Katalyst Light®) removes these through co-precipitation. For enhanced removal, use in combination with our high-capacity adsorbers:

These can remove Arsenic (III & V), Chromium (VI), Uranium, PFAS, PFOA, and many other heavy metals.

Standard designs are listed on page 3 of the Katalox Light® (Katalyst Light®) brochure. Alternatively, use the system calculator on the Katalox Light® (Katalyst Light®) homepage to estimate media volume and vessel size. Follow the operating conditions in the brochure for final system design.

The standard media lifespan of Katalox Light® (Katalyst Light®) is typically 7-10+ years with following proper system operating conditions.

- • Standard bag: 1 ft³ (28.3 L), approx. 30 kg (66.1 lb)

- • Big bag: 35.3 ft³ (1000 L), approx. 1085 kg (2392 lb)

- • Pallet: 40 bags, approx. 1225 kg (2700 lb)

Backwash when the pressure drop reaches ΔP 0.5-0.6 bar (7.3-8.8 psi) or based on system flow and application.

The two product are the same with different trade names.

Tags

Drinking Water Treatment

Drinking Water Treatment