Introduction

What is Red-Oxy® ? What is RED?

Red-Oxy® Generated Ferrate with Watch Water® process is the most stable form of Ferrate (VI) because it is generated with Ferric Hexahydrate granules. The oxidant used in this process is a strong acid halogen which generated high voltage of oxidant without any DBPs. REDOX potential of the oxidant is as high as Hydroxyl Radicals. Watch Water® has no doubt that its proprietary process will be commercialize world-wide with its own branches or through very close partners.

Best Features

• Removal of Toxic Cations

• Removal of Toxic Anions

• Oxidation of inorganic

• Oxidation of Organic Contaminants

• Destroy Pharmaceuticals and Personal Care

products

• Destroys endocrine disrupting chemicals

• Removal of pesticides fungicides and

herbicides

• Destroys all bacterial and viruses

• Destroys Petroleum Hydrocarbons

Application

This unique invention of Watch Water® can be

used to extract

• Phthalates

• Hormone-Disrupting chemicals used for softening plastics

• BPA – another endocrine-disrupting synthetic compound widely used in plastics and plastic bottles and hundreds of different consumer goods from thermal printing paper samples

• Polycyclic hydrocarbons

• Carcinogenic compounds formed from incomplete combustion of fuels from contaminated soil.

Watch Water® Germany is the only innovator to introduce the first On-Site REDX generator and the Strongest Oxidant Solution [SOS] generator for disinfection and adsorption of almost every contaminants in water. REDX technology combines salt of REDX, OXYX and ADSORBX to generate the most cost effective high capacity Oxidant, Disinfectant and Adsorbent with Real Chemistry on site. Our extremely intelligent and expertly designed REDX generators give all our customers the freedom to produce oxidants, disinfectants and adsorbents in the amount they need and when they need it. REDX will serve any kind of water in any kind of industries. REDX generators are available in different sizes to fit every applications and to produce much superior results compared to any other oxidants and disinfectants including adsorbents, available all over the water treatment market. REDX chemistries will clean over 7000 billion gallons of water everyday. Safer, economical and absolutely more effective REDX is just a new revolution in the process of making water neat, clean and safe and without any hazardous byproducts.

Red-Oxy® treatment can be done without investing on the equipments as in most of the systems worldwide the dosing equipment can be used from existing feed pumps which will bring substantial improvements in finished water quality, especially as regards to trace organic contaminants and DBPs.

RED is to reduce

Extremely Toxic organics and

Disinfection of water

Oxidation potential of over 8.5 V

Xtremely high sulfate and hydroxyl radicals

Yielding breakthrough in chemistry and process

Download Links

Brochure RED-OXY

MSDS RED

DILUTION PROCESS REDx

MSDS OXY

MSDS ADSORB

What is RED OXY?

RED-OXY Part I : General Description

RED-OXY Part II : Detailed Description

RED-OXY Simplified

Reference

RED-OXY LAB

Sludge Removal: RED-OXY LAB

See the first test result

See the second test reference

Lit: Oilfield Water Treatment

FREQUENTLY ASKED

QUESTIONS

RedOxy® is an advanced Oxidation–Adsorption–Filtration system developed by Watch Water® for complete water and wastewater purification. It combines three instant components — REDx, OXYx, and ADSORBx — to oxidize, disinfect, and adsorb contaminants simultaneously, producing clean and reusable water.

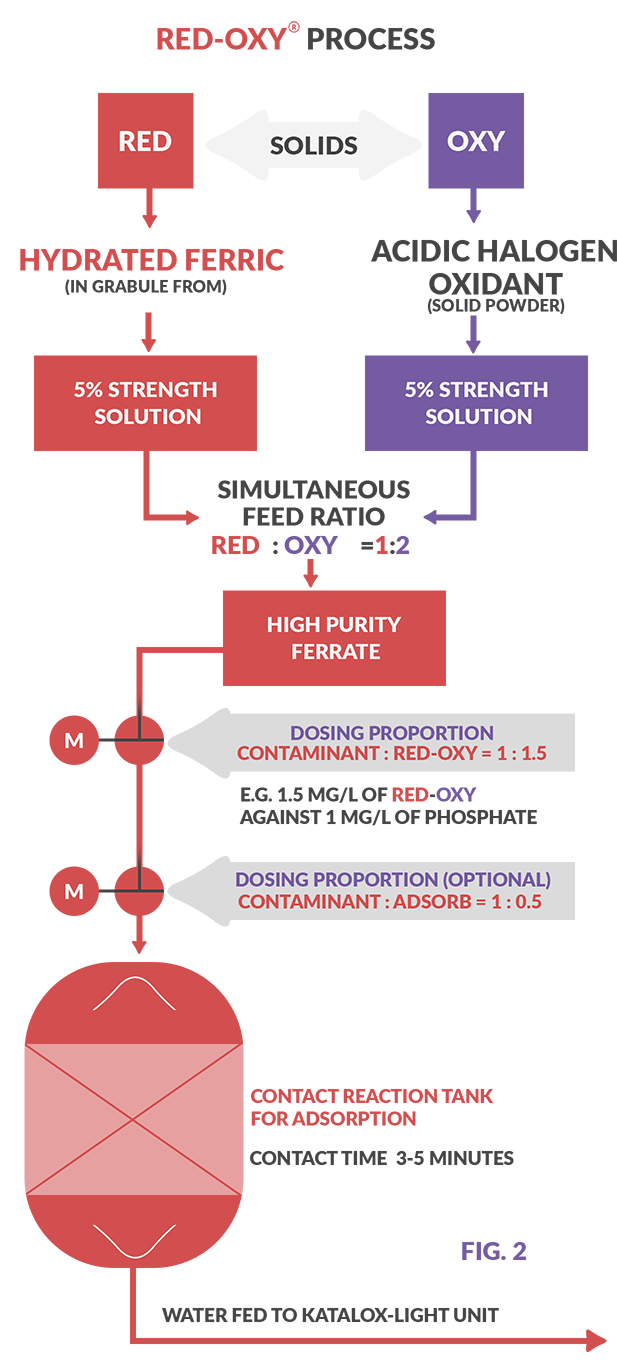

RedOxy® generates Ferrate (Fe⁶⁺) in situ by reacting hydrated ferric granules (REDx) with an acidic oxidant (OXYx). This produces ferrate ions (FeO₄²⁻) with extremely high oxidation potential (2.2 V), which rapidly oxidize pollutants. The ferrate then decomposes to ferric hydroxide (Fe(OH)₃), a powerful adsorbent that captures metals, anions, organics, and microbes — all within seconds.

Unlike chlorine or ozone, RedOxy® produces no disinfection by-products (DBPs) such as chloramines or bromates. It is non-toxic, non-corrosive, and biodegradable, offering faster reaction, lower cost, and no hazardous handling risks.

RedOxy® can be used for:

- ☛ Municipal and industrial wastewater

- ☛ Drinking water and groundwater

- ☛ Surface water and irrigation reuse

- ☛ Mining, fracking, oilfield produced water, and industrial effluents

It is effective on all waters containing organic, inorganic, and biological impurities.

RedOxy® removes a wide range of pollutants, including:

- ☛ Heavy metals: As, Pb, Cd, Cr, Cu, Hg, Mn, Fe

- ☛ Anions: Fluoride, Phosphate, Nitrate, Cyanide, Sulfate, Silicate

- ☛ Organics: Phenols, Nitro-aromatics, Pesticides, Hydrocarbons, EDCs

- ☛ Microbes: E. coli, viruses, spores, and pathogens

- ☛ Toxic gases: H₂S, NH₃, and odor-causing compounds

The process uses:

REDx – Hydrated ferric granules generating ferrate ions

OXYx – Acidic halogen-based oxidant producing hydroxyl and sulfate radicals

ADSORBx – Advanced ferric-hydroxide-based adsorbent with 3500 m²/g surface area

Together, they form the world’s most powerful oxidation–adsorption system.

RedOxy® achieves a combined oxidation-reduction potential (ORP) of up to 8.0 volts, derived from Ferrate (2.2 V), Hydroxyl radicals (2.7 V), and Sulfate radicals (3.1 V). This extremely high ORP ensures instant degradation of contaminants.

No. After oxidation, the only residue is Fe(OH)₃, an environmentally safe precipitate easily filtered by Katalox-Light®. RedOxy® produces no chlorinated or mutagenic compounds, unlike chlorine or chlorine dioxide.

Reactions occur within seconds to a few minutes, depending on pollutant load. Most metals and organics oxidize instantly, followed by rapid adsorption and filtration.

Yes. RedOxy® can be retrofitted into most existing plants using standard dosing pumps and tanks. No new infrastructure is required — only precise dosing control using the REDx/OXYx solutions.

☛ For a 5 % prepared solution:

☛ REDx: 250 ml/m³

☛ OXYx: 500 ml/m³

☛ ADSORBx: 250 ml/m³

☛ (Adjustable depending on contaminant level and total dissolved solids.)

Watch Water® recommends:

KATALOX-LIGHT® for main filtration of ferric hydroxide flocs and metals

CATALYTIC CARBON® as a polishing filter for trace organics, color, and odor removal

Yes. RedOxy® eliminates the need for chlorine, ozone, and other hazardous oxidants. It provides equal or better disinfection without DBPs, and it destroys all viruses, bacteria, and biofilm-forming organisms.

The system is fully adaptable to brackish water and seawater, maintaining oxidation efficiency up to 50,000 mg/L TDS, unlike chlorine-based systems that lose performance in saline conditions.

RedOxy® oxidizes hydrogen sulfide (H₂S) to sulfate safely without forming toxic chlorine by-products. It removes heavy metals, prevents scaling, eliminates biofouling, and produces reusable water for reinjection or hydraulic fracturing.

It oxidizes As(III) to As(V) within milliseconds and precipitates metals as insoluble ferric compounds, enabling 99.9 % removal through filtration. The process meets drinking-water standards (0.0 µg/L) at minimal cost.

Yes. The oxidation step decomposes complex organic molecules into CO₂ and water, reducing BOD, COD, TOC, color, and odor within minutes. The addition of ADSORBx enhances adsorption of dissolved organics.

It’s a compact on-site testing kit for real-time analysis and demonstration of RedOxy® performance. It allows treatment companies to test oxidation, adsorption, and filtration efficiency directly at client sites before full-scale installation.

- ☛ 100 % biodegradable and non-toxic

- ☛ No hazardous gas emissions or DBPs

- ☛ No handling of chlorine, ozone, or acids

- ☛ Minimal sludge generation

- ☛ Safe for workers and equipment

RedOxy® integrates oxidation, adsorption, and filtration into a single, compact, and cost-effective system. It delivers faster reactions, complete disinfection, no harmful by-products, and exceptional water reuse quality — truly the next-generation green chemistry for water and wastewater treatment.

Drinking Water Treatment

Drinking Water Treatment