Granulated Activated Carbon

Introduction

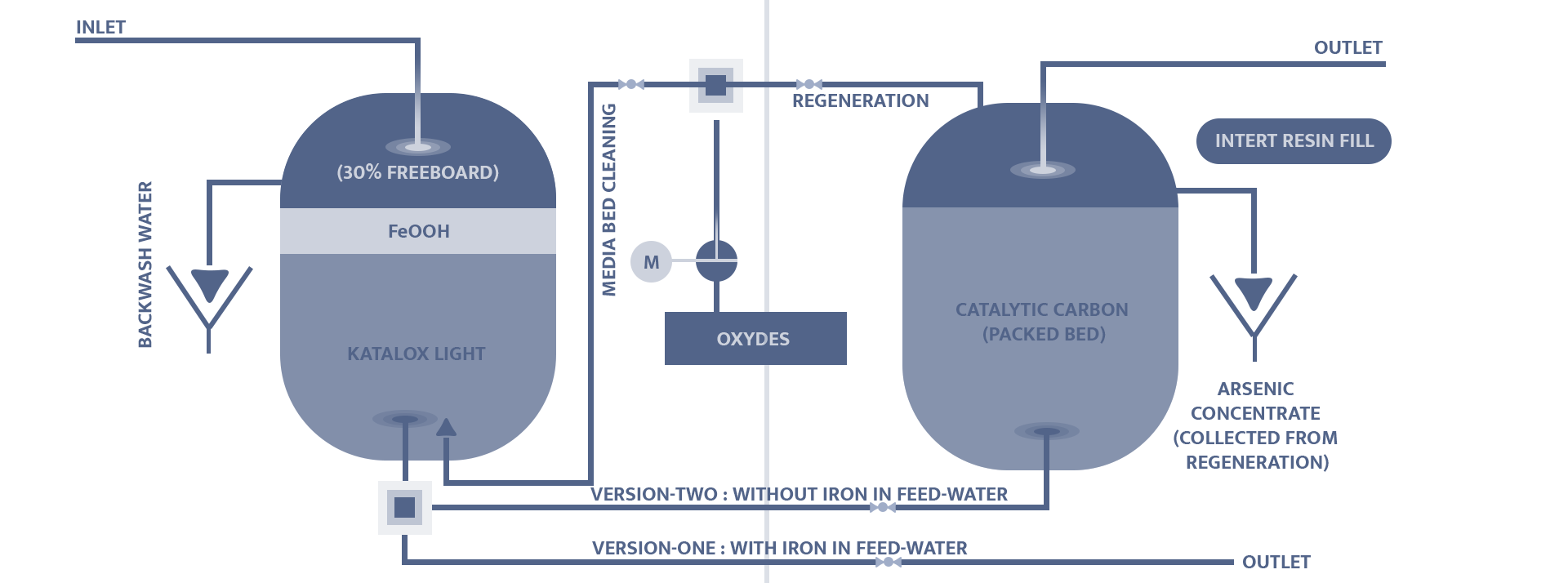

CATALYTIC CARBON is made of activated coconut shell carbon. This Granulated Activated Carbon which is (highly

activated) by catalysed iron-hydroxide, which enhances the adsorption of contaminants that have negative charge. CATALYTIC CARBON is the only available Carbon in the market which is regenerable. Iron Catalyst has the highest Oxidation and Adsorption pores “Inside as well as Outside the Activated Carbon.

Media Description: High content (10%) Feroxyhyte (FeOOH) coated GAC

CATALYTIC CARBON Removal methods:

1. Mechanical Filtration (fine particles, TSS, Turbidity down to 1 micron)

2. Adsorption of organic contaminants

3. Adsorbtion of inorganic contaminants (e.g. As, Heavy Metals, Radionuclides)

| Filtration (≤ 1 µm) of | Removal of | Best features | Regeneration of Catalytic-Carbon with OXYDES-P |

|---|---|---|---|

| Total Suspended Solids | Humic Substances | Feroxyhyte coated Granular Activated Carbon | Usage: 1% Concentrated Solution of OXYDES-P |

| Sediments | Tanins & Lignin | Very high surface area | Usage: 1% Concentrated Solution of OXYDES-P |

| Turbidity | Color & Odor (organic) | Chemically Regenerable with OXYDES & OXYDES-P | |

| Chloramines | No mandatory dosing required | ||

| Trihalomethanes (THMs) | Light weight media - saves backwash water | ||

| Phenols & p-nitro phenol | Replacement frequency : every 2 - 5 years | ||

| All kind of Dyes | pH regulation in the range of 6.5 - 6.9 is strongly recommended for removal of Cr(III) and As(III) | ||

| Phenols & p-nitro phenol | |||

| Inorganic (Arsenate, Arsenide, Chromium, Copper, Cyanide, Fluoride, Lead, Mercury & Selenium) |

FREQUENTLY ASKED

QUESTIONS

CATALYTIC CARBON® is a high-activity coconut-based Granular Activated Carbon (GAC) enhanced with iron catalyst coating. This catalytic structure increases oxidation and adsorption performance, allowing it to remove a wide range of organic and inorganic contaminants from water and wastewater. It is NSF/ANSI/CAN 61 certified for drinking water use and manufactured in Germany by Watch Water® GmbH.

Unlike conventional activated carbon, which only adsorbs contaminants, CATALYTIC CARBON® has:

- ☛ Iron-hydroxide coating (20–50 nm) that adds oxidation ability

- ☛ High surface area (2,000–2,500 m²/g) for faster reaction rates

- ☛ Positive surface charge that attracts negatively charged pollutants

- ☛ Regenerable structure — it can be cleaned and reused with OXYDES-P®

This combination removes organics, metals, and disinfectant by-products more effectively than standard carbon.

CATALYTIC CARBON® removes and adsorbs a wide range of contaminants:

Organic Compounds- ☛ Humic & Fulvic acids

- ☛ Tannins, lignins, color & odor compounds

- ☛ Phenols (e.g., p-nitrophenol)

- ☛ Cyanides

- ☛ Trihalomethanes (THMs)

- ☛ Chloramines

Heavy Metals

- ☛ Arsenic, Boron, Chromium, Copper, Lead, Mercury

- ☛ Phosphates, Bromides

It’s also effective for chlorine/chloramine reduction and improving taste and odor in drinking water.

- ☛ Municipal drinking water and point-of-entry / point-of-use systems

- ☛ Beverage production and process water

- ☛ Industrial wastewater and reuse systems

- ☛ Swimming pools and aquariums

- ☛ Protection of ion-exchange and RO systems from organics and chloramines

It’s suitable for any application where oxidation and adsorption are needed in one media.

The iron-catalyzed surface reacts with and adsorbs contaminants through:

- ☛ Electrostatic attraction (positive surface binds negative organics)

- ☛ Catalytic oxidation (iron hydroxide promotes redox reactions)

- ☛ Physical adsorption (large micro- and mesopores capture molecules)

This dual action makes it highly efficient for color, odor, and heavy-metal removal.

It can be regenerated easily using OXYDES-P®, a catalyzed superoxide regenerant. Simple procedure:

- ☛ Backwash – 5–10 minutes

- ☛ Inject 1% OXYDES-P® solution – 15–30 minutes

- ☛ Fast rinse – 5–10 minutes

- ☛ Return to service

For every 100 liters of media, use 1 kg of OXYDES-P® mixed in 100 L of water. Regeneration is typically done every 6 months. The process restores the media to nearly new condition.

With proper operation and regeneration, the media lasts 2–5 years, depending on water quality and contaminant loading. The carbon can be regenerated multiple times without losing structural integrity.

Yes. During the first installation, soak the media for 45 minutes in water containing 1 tablespoon of salt per 30 L bag, then backwash until clear (about 20 minutes). This activates surface sites and ensures optimal catalytic performance.

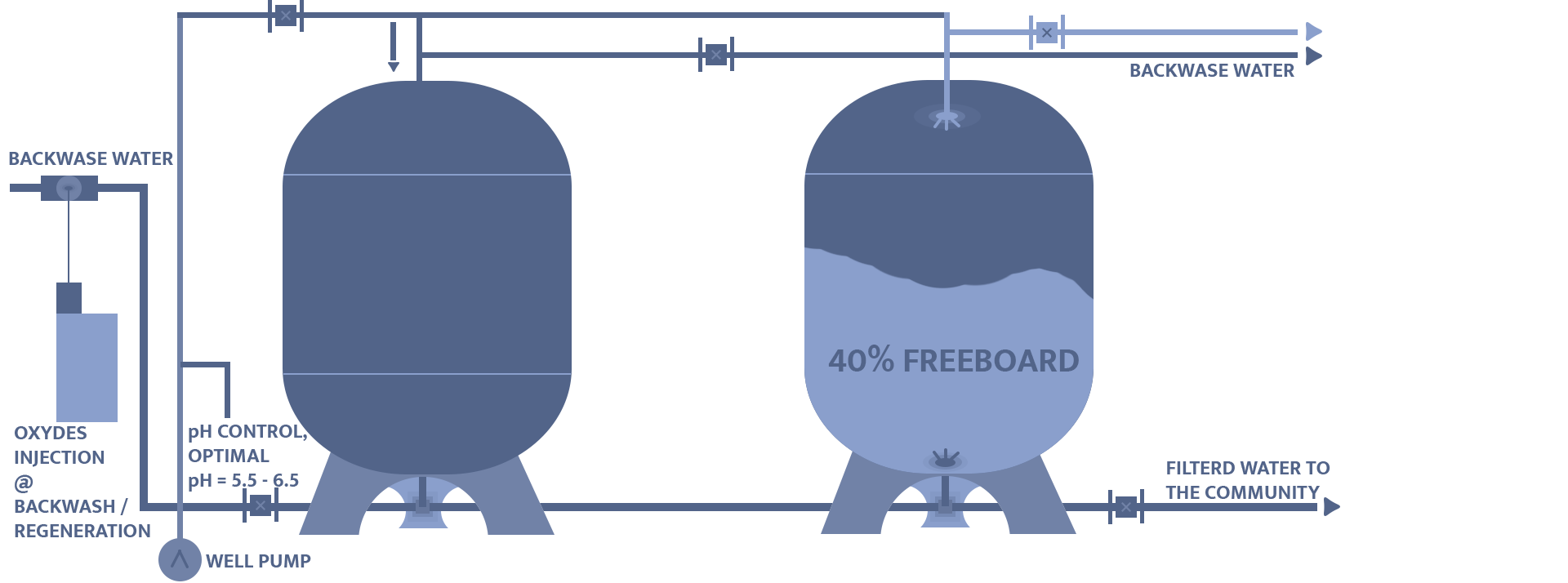

| Flow Direction | Down-flow (or up-flow packed bed) |

| Freeboard | 25 – 35 % |

| Filtration Rate | 10 – 20 m/h (max. 40 BV/h) |

| Bed Contact Time (EBCT) | ≥ 90 seconds |

| Bed Depth | 80 – 100 cm (max. 120 cm) |

| pH Range | Up to 9.5 |

| Backwash Velocity | 10 – 20 m/h |

| Regeneration | Every 6 months (with OXYDES-P®) |

Pilot testing is recommended for industrial applications or high contaminant loads.

| Appearance | Red-black coarse granules |

| Mesh Size | 8 × 30 (0.6 – 2.4 mm) |

| Bulk Density | 630 – 640 kg/m³ |

| Moisture | ≤ 5 % |

| Surface Area | 2,000 – 2,500 m²/g |

| Hardness | 98 % (min.) |

| Regenerable | Yes |

| Expected Service Life | 2–5 years |

- ☛ 30 L Bags (19.2 kg each) – 40 bags per pallet (≈793 kg gross)

- ☛ 1,000 L Bulk Bags (≈665 kg net) – 1 per pallet

Other packaging options available upon request.

| Technology | Limitation | Catalytic Carbon® Advantage |

|---|---|---|

| Ion Exchange | Requires chemical regeneration; limited organic removal | Regenerable with OXYDES-P®, adsorbs organics + metals |

| Membrane Filtration | High cost, fouling, requires pre-treatment | Low-cost, simple, reusable |

| Conventional Carbon | Only adsorption; poor oxidation | Dual function – oxidation + adsorption |

| Chemical Oxidation | Generates sludge or by-products | Clean oxidation via iron catalyst |

Yes. CATALYTIC CARBON® is NSF/ANSI/CAN 61 certified and safe for drinking water treatment. It does not add chemicals or metals to water and leaves no harmful residues.

- ✅ Removes multiple contaminants in one step

- ✅ Regenerable and long-lasting (2–5 years)

- ✅ Works at neutral or slightly alkaline pH

- ✅ High surface area for superior adsorption

- ✅ NSF-certified for potable water

- ✅ Simple regeneration using OXYDES-P®

- ✅ Made in Germany — reliable, consistent quality

Watch Water GmbH, Mannheim, Germany – a global leader in sustainable water treatment technologies. The company specializes in adsorbers, catalysts, and regenerative oxidation systems such as Ferrolox®, Titansorb®, Filtersorb®, and OXYDES-P®.

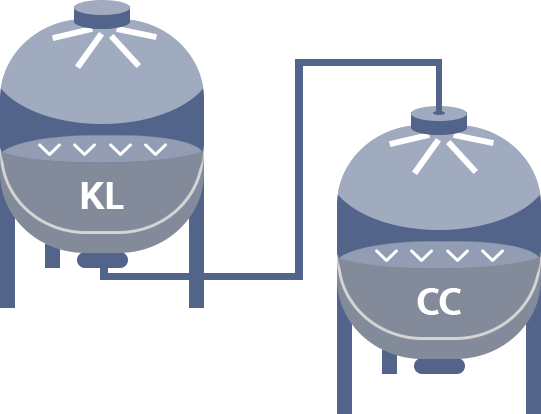

Drinking Water Treatment

Drinking Water Treatment