Introduction

Turbidity is the term given to anything that is suspended in a water supply. It is mostly found in surface waters. However, it doesn’t exist in groundwaters aside from in shallow wells and springs after substantial heavy rains. Similarly, turbidity gives the water a shady appearance or appears as dirty sediment. Undissolved materials, e.g. sand, mud, residue or suspended iron is added to turbidity, which can cause the recoloring of sinks and apparatuses and the staining of textures.

An excessive amount of green growth or sediment in lakes and streams can make them inadmissible for diversion and aquatic life. For instance, turbidity is caused by particles suspended or broke down in water that scatters light making the water seem shady or dinky.

Above all, turbidity is an indicator of health risk. Science has demonstrated that as turbidity increases, the risk to human health also increases. Particularly harmful to babies, adults, and individuals with compromised immune systems (e.g. those with HIV/Aids, experiencing chemotherapy, or taking anti-rejection drugs.

Normally turbidity is measured in NTUs (nephelometric turbidity units). Typical drinking water will have a turbidity level of 0 to 1 NTU. Similarly, turbidity can be measured in mg/l and it’s size is measured in microns.

Excessive turbidity in drinking water is aesthetically unappealing, and may likewise causes health concern. It can give food and shelter to pathogens. If not expelled, turbidity can promote regrowth of pathogens in the distribution system, prompting waterborne infection outbreaks, which have caused huge instances of gastroenteritis all through the world.

HOW TO REMOVE TURBIDITY?

2.1 USING KATALYST LIGHT

- • Highly advanced KATALYST LIGHT® is very efficient in turbidity removal along with iron and manganese. KATALYST LIGHT® is the best iron and manganese removal media which can also remove low to moderate levels of Turbidity.

- • You know what’s make KATALYST LIGHT® best?

- > Operational pH 5.8-10.5

- > 40% Freeboard

- > Filtration < 3 microns

- > Coating of MnO2 10%

- > Treats iron and manganese with high capacity, which is not possible with other competitive medias available in the market.

- • Unlike other conventional filter media, KATALYST LIGHT® does not very frequent regeneration, which makes it unique in the industry.

- • Mechanical Filtration (fine particles, TSS, Turbidity, etc.)

- • Installation of KATALYST LIGHT® system for removal of Turbidity, iron and manganese is very simple. This can be performed by few simple instructions by Watch Water.

2.2 USING ZEOSORB

- > Zeosorb® has been introduced to the process purification of drinking water and wastewater due to its large specific surface area and the selective adsorption of substances. For instance, ammonia dissolved organic matter and many other cations.

- > All drinking water standards for microorganism pathogens and turbidity removal can easily meet by using a natural, relatively low-cost material, such as Zeosorb® rather than “Sand” which is mainly quartz grains.

- > Removal of suspended particles and Turbidity.

2.3 RIVER WATER TURBIDITY

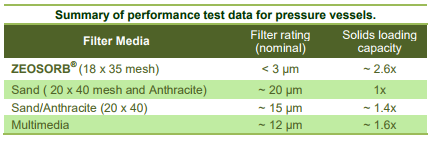

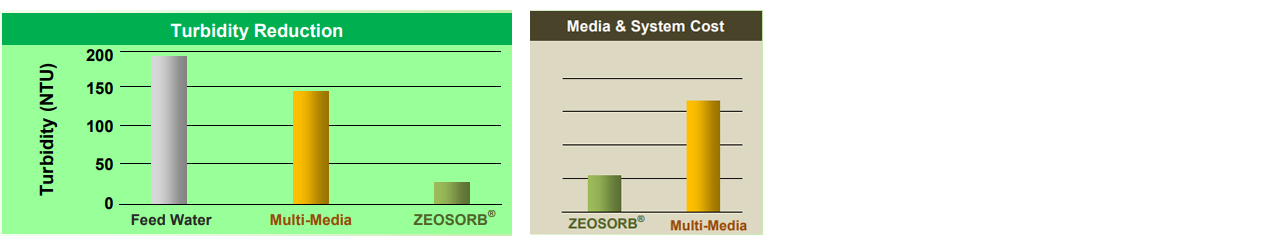

The test of ZEOSORB vs Multimedia Media filtration was conducted for fine particle (turbidity) removal from river water. Pressure vessels (18″ diameter) were operated with a service flow of 36.7 m/h of bed area for six consecutive days and turbidity (NTU) was measured in the feed and filtered water. The filtered water average NTU was approximately 1/3 of the multimedia filtrate, indicating superior fine particle removal by Zeosorb®.

2.4 BENEFITS

Better Filtrate Clarity: Typical Sand/Anthracite filter beds have a 12 to 15-micron nominal filter rating. However, Zeosorb® typically would have a nominal filer rating of less than 3 microns. This property greatly reduces the effluent turbidity, generally measured in National Turbidity Units (NTUs).

Increased flow rate in gravity System: In a Sand/Anthracite filter media system the flow rate is typically 3 to 5 m/h. However, in a Zeosorb® filter media system, the flow rate is typically in the 10 m/h range.

Increased flow rate in pressure vessel systems: In a Sand/Anthracite pressure vessel filter system the flow rates are typically 15 to 17 m/h. However, in a Zeosorb® pressure vessel filter system the flow rates are typically in the 29 to 37 (and sometimes 48) m/h range.

Lower capital requirement to increase Filtration Capacity: Generally, the capacity of a filter plant can be doubled with no increase in the plant by switching the filter media to Zeosorb®.

Fewer Backwash cycles: Zeosorb® requires only one-half of the backwash cycles that are required by Sand/Anthracite.

Less Backwash water: The fewer backwash cycles generally cut the amount of backwash water by one-third to one-half. This means treating less backwash water and greater plant capacity.

Greater Loading due to greater surface area: Zeosorb® generally has 6 to 7 times the surface area as compared to Sand. This makes Zeosorb® a much better filter media with greater holding capacity.

Long media bed life: The anticipated filter bed life of Zeosorb® is 10 years.

Land application of spent Zeosorb® media: Under most conditions, Zeosorb® filter bed can be applied to lawns and gardens as soil amendments.

Better Cleaning: Active, dynamic, bed tumbling and mixing during backwash efficiently cleans bed granules.

Drinking Water Treatment

Drinking Water Treatment