BOILER DOSING CHEMICALS

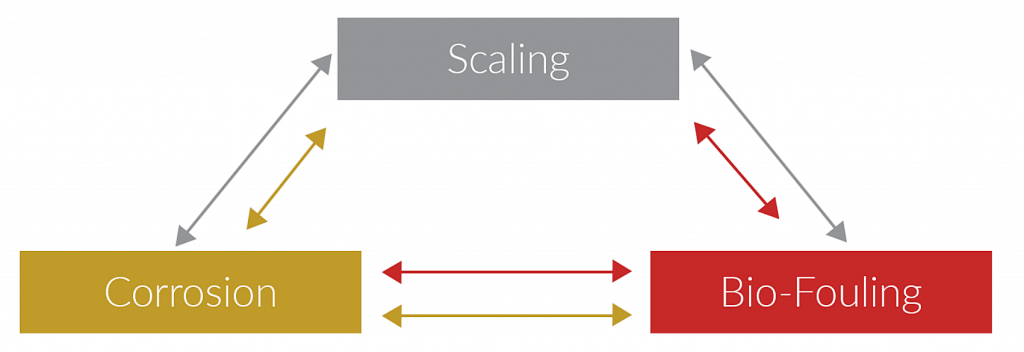

Boilers are meant to heat up water, the vapours from which can be used for cooking, sanitation or for other industrial purposes. Boiler water treatment is basically the treatment and conditioning of feed water with three primary goals, i.e., corrosion prevention, scale prevention and maintaining steam purity and quality.

Preventing Boiler Corrosion is done through the removal of oxygen and maintaining appropriate alkalinity levels in the boiler water to prevent acid attack. Increasing temperature and using an oxygen scavenger helps remove oxygen, but it may cause precipitation of hardness salts. These hardness salts can be removed externally using a water softener or internally antiscalants/scale inhibitors.

How to make a difference

Boiler Protection

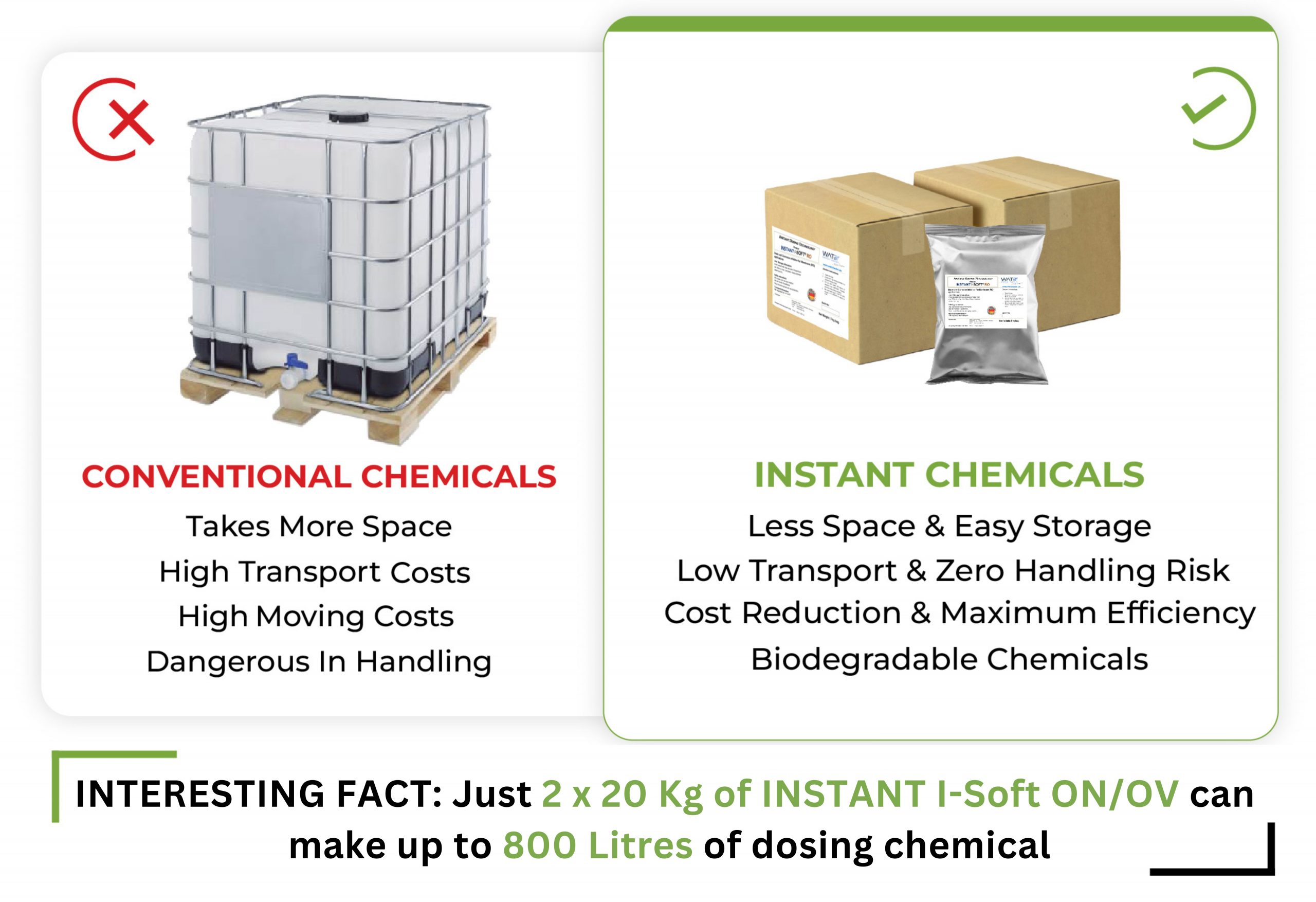

Watch Water is a boiler water treatment specialist, developing and delivering a wide range of dosing chemicals to keep your plant running safely, efficiently, and economically. Watch Water’s multi-component boiler water treatment chemicals- INSTANT I-SOFT ON and INSTANT I-SOFT OV, combine the ease of a single chemical treatment product with multifunctional protective capabilities to provide excellent all-around boiler protection.

The INSTANT I-SOFT ON and INSTANT I-SOFT OV stabilize all Polyvalent metal ions, which means it increases the rate at which the metals dissolves. Both INSTANT I-SOFT ON and INSTANT I-SOFT OV are in alkaline range, which is the optimum pH range for the boilers, hence they stop corrosion, neutralizes any kind of hardness and avoids all kinds of acid cleaning steps.

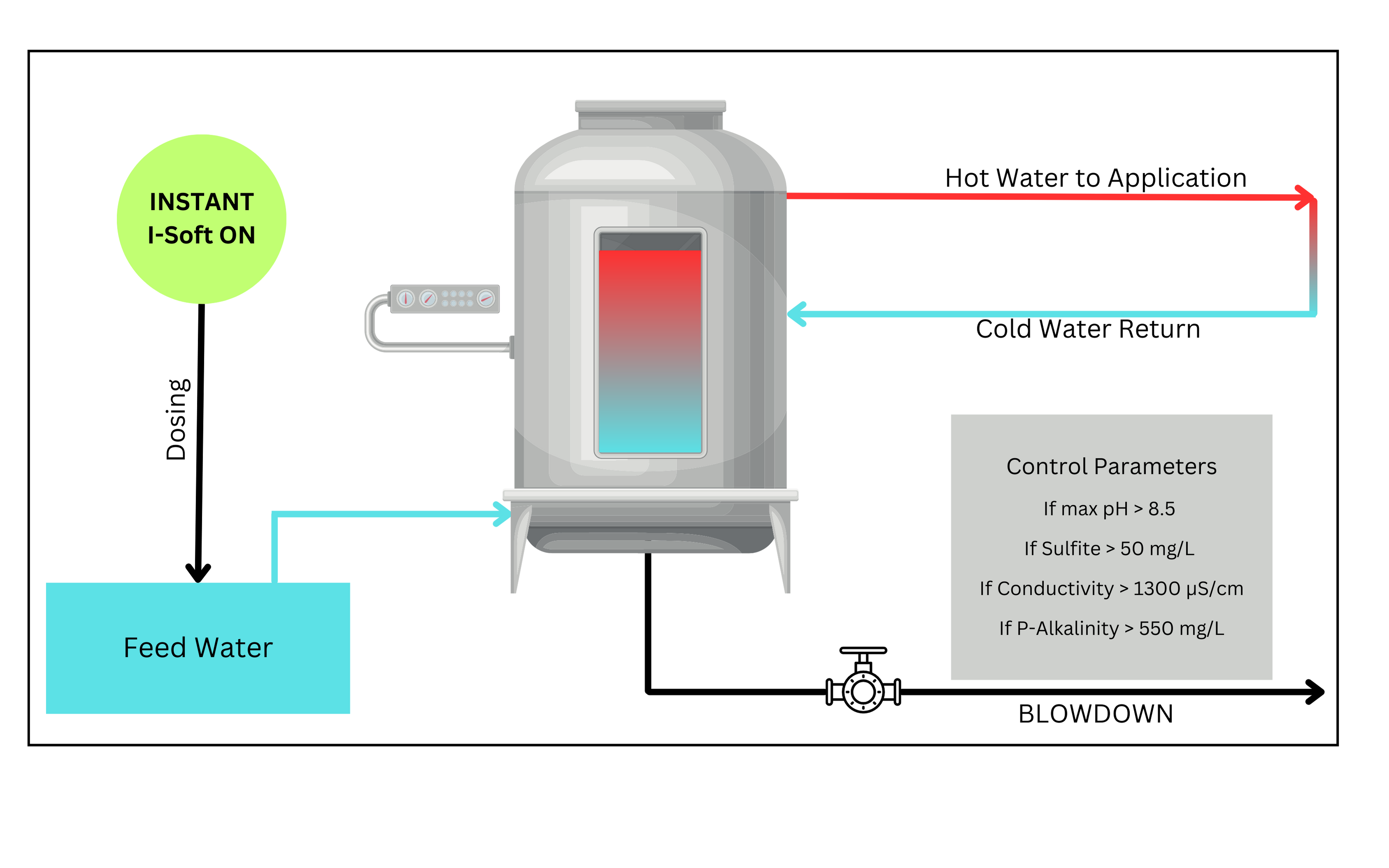

HOT WATER BOILER

I-Soft ON

- • Scale & Corrosion inhibitor with NON-VOLATILE OXYGEN SCAVENGERS

- • Can be fed continuously in the make-up line or directly into water circulation.

- • Dosing rate: 40 – 120 ml of 5% strength diluted solution (2 – 6 mg/L of solid product) for each cubic meter (1000 liters) of water. Proportional dosing is only when the water is fed in the boiler.

- • Keywords: Non-Volatile Oxygen Scavenger, Corrosion prevention, Scale Prevention, Alkalinity Builder, Hot water boiler protection, Closed System Boiler, Instant Dosing Chemical.

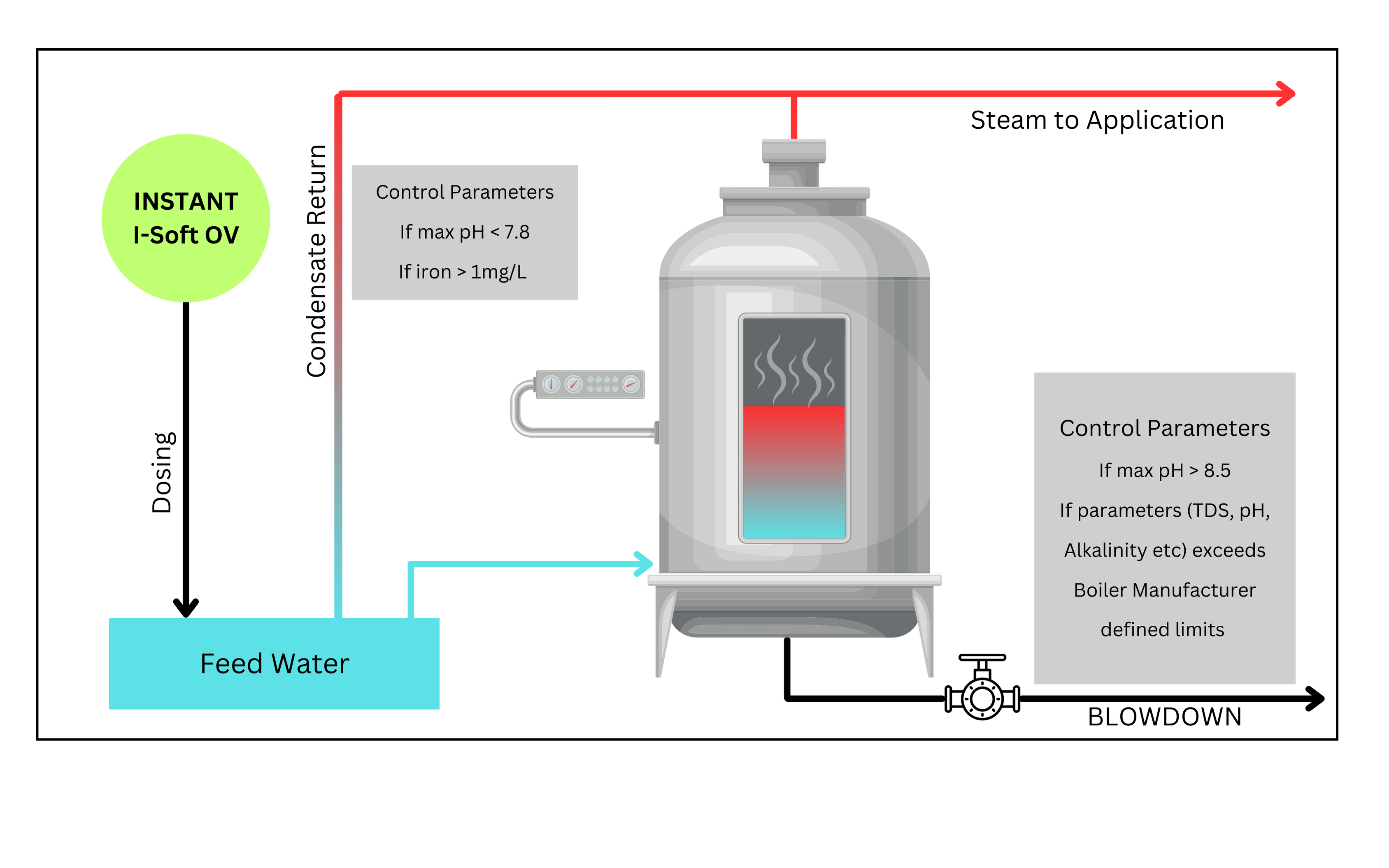

STEAM BOILER

I-Soft OV

- • Scale & Corrosion inhibitor with VOLATILE OXYGEN SCAVENGERS.

- • Substitute for Hydrazine but does not contribute any hazardous byproducts.

- • Breaks down to form amines which elevate the pH of the condensate systems.

- • Dosing rate: 40 – 120 ml of 5% strength diluted solution (2 – 6 mg/L of solid product) for each cubic meter (1000 liters) of water. Proportional dosing is only when the water is fed in the boiler.

- • Keywords: Volatile Oxygen Scavenger, Corrosion prevention, Scale Prevention, Alkalinity Builder, Steam water boiler protection, Condensate treatment Instant Dosing Chemical.

Drinking Water Treatment

Drinking Water Treatment